The 2.4 Ecotec engine, developed by General Motors, is a reliable 4-cylinder powerplant known for its efficiency and performance. Built with an aluminum block, it delivers excellent fuel economy and durability. Initially introduced in various GM vehicles, the engine features advanced timing chain technology, including guide bolts that ensure proper chain tension and alignment, crucial for smooth operation and longevity.

1.1 Overview of the Ecotec Engine Family

The Ecotec engine family, developed by General Motors, is renowned for its efficiency, durability, and innovative design. Introduced in the 1980s, these engines feature lightweight materials, advanced combustion systems, and variable valve timing. The 2.4 Ecotec stands out as a high-performance variant, combining fuel efficiency with robust power delivery. Its compact design and modular components make it versatile across various GM vehicles, ensuring reliability and cost-effectiveness.

1.2 Applications of the 2.4 Ecotec Engine

The 2.4 Ecotec engine is widely used in various GM vehicles, including Chevrolet, Buick, and GMC models. It powers compact cars, SUVs, and crossover vehicles, delivering a balance of fuel efficiency and performance. Its versatility and reliability make it a popular choice for both everyday driving and more demanding applications, ensuring smooth operation across diverse vehicle types and driving conditions.

Understanding the Timing Chain System

The timing chain system in the 2.4 Ecotec engine synchronizes valve and piston movements, ensuring efficient combustion. It includes chains, sprockets, and guide bolts, crucial for precise timing and engine durability.

2.1 Function of the Timing Chain

The timing chain in the 2.4 Ecotec engine plays a critical role in synchronizing the rotation of the crankshaft and camshaft. It ensures that valves open and close in precise harmony with piston movements, preventing engine damage and optimizing performance. The chain’s durability and tension are maintained by guide bolts, which stabilize its position and prevent misalignment or wear.

2.2 Components of the Timing Chain System

The timing chain system in the 2.4 Ecotec engine includes the chain itself, tensioners, sprockets, and guide bolts. The chain consists of durable metal links that pivot around sprocket teeth, while tensioners apply pressure to maintain proper tension. Guide bolts stabilize the chain’s position, preventing lateral movement, and sprockets connect the chain to the crankshaft and camshaft gears, ensuring synchronized engine operation.

The Role of Guide Bolts in the Timing Chain

Guide bolts stabilize the timing chain, ensuring proper alignment and preventing lateral movement. Made from durable materials like stainless steel, they maintain chain tension and prevent engine damage.

3.1 What Are Timing Chain Guide Bolts?

Timing chain guide bolts are small, durable fasteners that secure the timing chain guides in place. Typically made from high-strength materials, they prevent chain misalignment and wear. These bolts are crucial for maintaining the timing chain’s stability, ensuring proper engine operation and preventing costly damage. Regular inspection is recommended to avoid failure.

3.2 Importance of Guide Bolts for Engine Performance

Guide bolts play a critical role in maintaining timing chain stability, ensuring proper engine timing and performance. They prevent chain misalignment, which can cause engine misfires, reduced efficiency, and potential damage. Securely positioned guide bolts promote consistent chain tension, minimizing wear on related components and preventing costly repairs. Their integrity is vital for smooth engine operation and longevity.

Symptoms of Worn Timing Chain Guide Bolts

Worn timing chain guide bolts can cause rattling noises, engine misfires, and reduced performance. If neglected, they may lead to complete chain failure, resulting in costly repairs.

- Rattling or knocking sounds from the engine.

- Decreased engine power and efficiency.

- Check Engine Light illumination.

- Difficulty accelerating smoothly.

4.1 Common Indicators of Wear

Worn timing chain guide bolts often manifest through distinct symptoms. These include a rattling or knocking noise from the engine, especially during acceleration or idle. Additionally, drivers may notice a decrease in engine performance, such as misfires or rough idling. The Check Engine Light may illuminate, indicating issues with the timing chain system. These signs highlight the need for immediate inspection to prevent further damage.

- Rattling or knocking engine noises.

- Decreased engine performance.

- Check Engine Light activation.

4.2 Consequences of Ignoring Wear

Ignoring worn timing chain guide bolts can lead to severe engine damage. The timing chain may slip or break, causing misfires and potentially bending valves or damaging pistons. This can result in costly repairs, including replacing the entire timing chain system or even the engine itself. Prompt attention is crucial to avoid these expensive and time-consuming consequences.

- Timing chain failure.

- Engine misfires and reduced performance.

- Potential valve or piston damage.

- Increased repair costs.

Replacement and Maintenance

Regular inspection and timely replacement of timing chain guide bolts are essential for maintaining engine health. Worn bolts should be replaced immediately to prevent chain misalignment.

- Inspect guide bolts every 50,000 miles.

- Replace worn or damaged bolts promptly.

- Use torque wrench for proper tightening.

5.1 When to Replace Timing Chain Guide Bolts

Timing chain guide bolts should be replaced if they show signs of wear, such as excessive play, rust, or stripped threads. Additionally, if the engine produces unusual noises like clattering or rattling, it may indicate loose or damaged guide bolts. Replacement is also necessary if the timing chain is misaligned or if the engine experiences reduced performance due to improper chain tension.

- Visible wear or damage to the bolts.

- Unusual engine noises during operation.

- Loss of proper timing chain alignment.

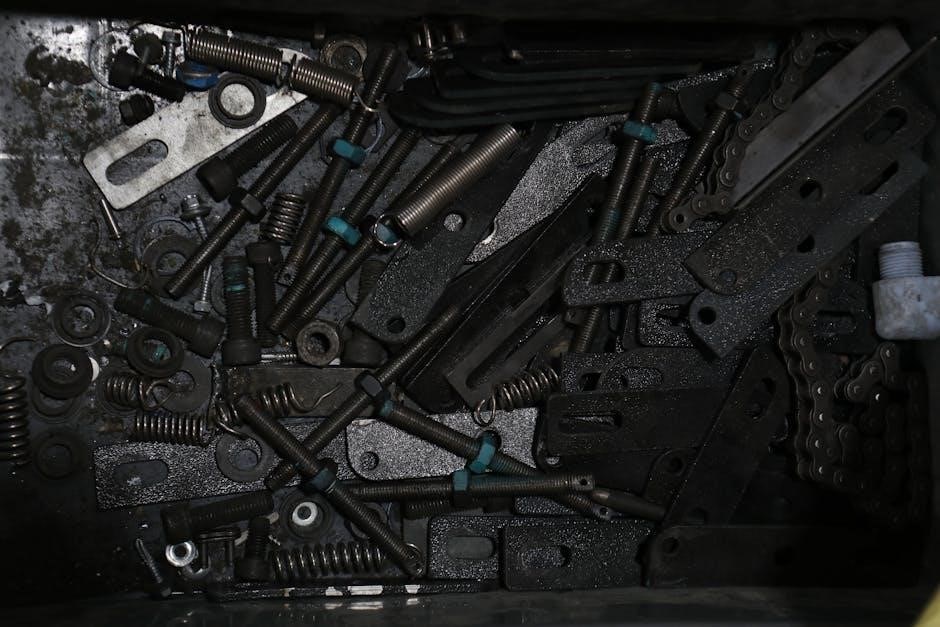

5.2 Tools and Materials Needed for Replacement

To replace the timing chain guide bolts, you’ll need a socket set, wrenches, a torque wrench, and a breaker bar for stubborn bolts. Additionally, new guide bolts, washers, and threadlocker are essential. A gasket sealant may be required if removing the cover. Ensure all tools are compatible with the engine’s specifications to avoid damage during the replacement process.

- Socket set and wrenches.

- Torque wrench and breaker bar.

- New guide bolts and washers.

- Threadlocker and gasket sealant.

Preventive Measures

Regular inspections, proper lubrication, and avoiding aggressive driving help maintain timing chain guide bolts. Using high-quality parts ensures longevity and prevents premature wear.

- Regular inspections of guide bolts.

- Proper lubrication of moving parts.

- Avoiding aggressive driving habits.

- Using high-quality replacement parts.

6.1 Regular Inspection Guidelines

Inspect timing chain guide bolts every 30,000 to 50,000 miles. Check for signs of wear, such as loose bolts or metal shavings. Ensure proper torque specifications are met. Lubricate moving parts and replace worn components promptly. Regular maintenance prevents costly repairs and ensures optimal engine performance.

6.2 Best Practices for Longevity

To ensure longevity, always use high-quality replacement parts and adhere to manufacturer torque specifications. Regularly lubricate moving components and avoid excessive force during installation. Keep the engine clean and inspect for wear during routine maintenance. Proper alignment and tension of the timing chain system are critical for extended service life and optimal performance.

Common Failures and Solutions

Common failures include worn guide bolts causing timing chain misalignment. Solutions involve replacing worn bolts and ensuring proper torque to maintain chain stability and prevent engine damage.

7.1 Known Issues with the 2.4 Ecotec Timing Chain

The 2.4 Ecotec timing chain system is prone to guide bolt wear, leading to chain misalignment and rattle. Premature wear often stems from improper installation or lack of maintenance. Additionally, the chain tensioner can fail, causing similar symptoms. Addressing these issues early is crucial to prevent costly engine damage and ensure optimal performance.

7.2 Case Studies and Solutions

A common issue reported in the 2.4 Ecotec engine involves timing chain guide bolts wearing out prematurely, leading to chain rattle and reduced engine performance. In one documented case, a driver experienced persistent engine noise and power loss, which were traced to worn guide bolts. Replacement of the bolts and proper tightening resolved the issue. Regular inspections and timely replacements are recommended to prevent such problems.

Torque Specifications and Installation

Align the timing chain with engine gears, ensuring proper tension; Tighten guide bolts in the specified order. Perform a final torque check for security and accuracy.

8.1 Proper Torque Values for Guide Bolts

The timing chain guide bolts on the 2.4 Ecotec engine typically require a torque of 25-35 ft-lbs. Always refer to the manufacturer’s specifications for precise values. Proper tightening ensures optimal performance and prevents engine damage. Use a torque wrench to achieve the correct tension, following the recommended sequence to maintain alignment and functionality of the timing chain system.

8.2 Step-by-Step Installation Guide

Ensure the engine is cold and in a stationary position.

Remove the timing chain cover and water pump for access.

Align the timing chain with the crankshaft and camshaft marks.

Install the guide bolts, ensuring they are securely fastened.

Tighten the bolts to the recommended torque specification.

Reinstall the timing chain cover and water pump.

Start the engine and check for proper operation.

DIY vs. Professional Repair

DIY repair can save costs but requires mechanical skills and tools. Professional repair ensures reliability and warranty, ideal for complex or high-mileage engines, but is more expensive.

9.1 Pros and Cons of DIY Replacement

DIY replacement saves money and allows car owners to gain hands-on experience. However, it requires mechanical skills and specialized tools. Improper installation can lead to engine damage, making professional assistance sometimes necessary for reliability and warranty purposes. Balancing cost efficiency with technical expertise is key to a successful DIY timing chain guide bolt replacement;

9.2 When to Seek Professional Help

Seek professional help if you lack mechanical expertise or tools for timing chain guide bolt replacement. If symptoms like engine misfires or loud noises persist, a mechanic’s specialized knowledge is crucial. Improper installation can cause severe engine damage, making professional assistance safer and more reliable, especially for maintaining warranty validity and ensuring long-term performance.

The 2.4 Ecotec engine’s timing chain guide bolts play a critical role in its performance. Regular inspections and prompt replacements are essential to avoid costly repairs and ensure longevity.

10.1 Summary of Key Points

The 2.4 Ecotec engine’s timing chain guide bolts are vital for maintaining proper chain tension and alignment, preventing engine damage. Regular inspections and replacements are crucial to avoid costly repairs. Proper torque specifications and DIY vs. professional installation decisions should be considered. Preventive measures, such as inspections, ensure longevity. Understanding symptoms of wear and addressing them promptly is essential for optimal performance and durability.

10.2 Importance of Proper Maintenance

Proper maintenance of the 2.4 Ecotec timing chain guide bolts is essential for ensuring engine longevity and performance. Regular inspections and timely replacements prevent wear-related issues, avoiding costly repairs. Neglecting maintenance can lead to premature failure, potentially causing severe engine damage. Consistent care ensures optimal functionality, maintaining the engine’s reliability and efficiency over time.